project description

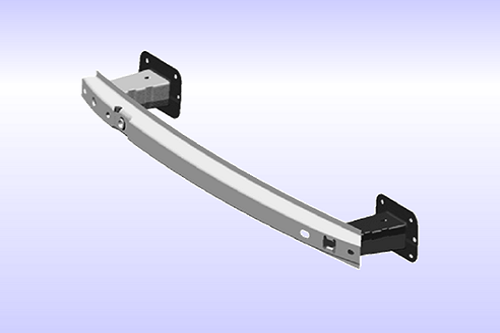

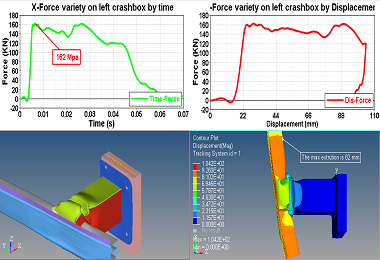

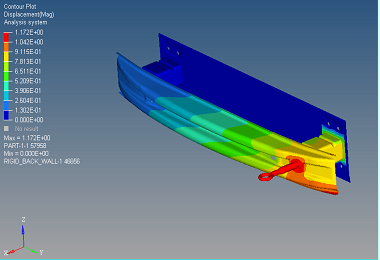

In the bumper design and development stage, the structural performance of the bumper is analyzed and optimized according to RCAR-AZT, RCAR-BUMPER, ECE-R42, TOWING, PILLAR_CRASH and other test regulations.

Analysis content

RCAR_AZT

RCAR_BUMPER

ECE_R42

TOWING

PILLAR_CRASH

Using the Software

HyperWorks, RADIOSS, ABAQUS

Analysis result

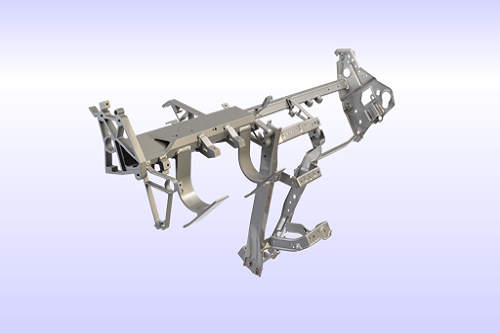

project description

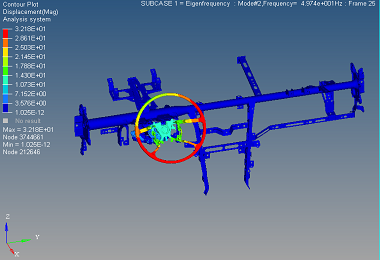

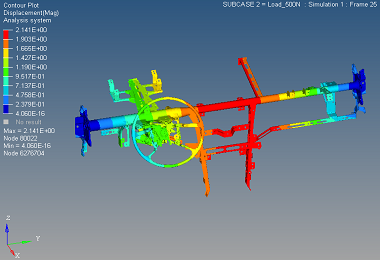

The dash cross member assembly design development phase, the dash cross member, steering column, steering wheel, vehicle etc. into rows operational modal stiffness, collision simulation performed by CAE analysis, designed to detect weaknesses and further Optimize and design the best products.

Analysis content

Modal analysis

Stiffness analysis

Sagging analysis

Side impact analysis

Knee hit analysis

Using the Software

HyperWorks, RADIOSS

Analysis result

Figure-1: CCB Modal Analysis Figure-2: Stiffness Analysis of CCB Mounting Fixed Points

project description

In the design and development stage of automotive exterior mirrors, we rely onGB15084 , ECE-R46 ,Each OEM and other test regulations require the creation of an FEA analysis model, and the vibration of the exterior mirrors is analyzed by FEA software., strength and wind noise performance.

Analysis content

Natural frequency

Frequency response

Strength ( involving material nonlinearity and contact )

Wind noise

Using the Software

HyperWorks, ANSYS, Fluent

Figure-1: Rear view mirror modal analysis Figure-2: Rear view mirror strain energy

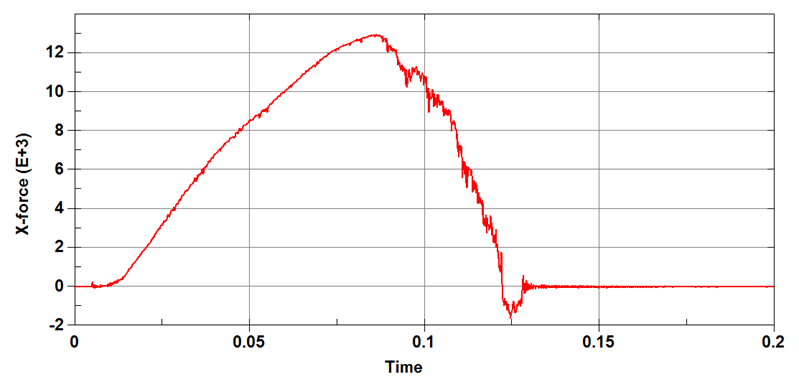

project description

With the increasing number of cars, people have higher and higher requirements for car safety performance. Automobile safety performance is divided into active safety and passive safety. Passive safety is a rapidly developing field in the automotive industry. The strength of the car seat is an important indicator of passive safety of the car.

Analysis content

Seat belt fixed point strength analysis

Positive impact analysis

Post-touch analysis

Luggage collision analysis

Head pillow static strength analysis

Using the Software

HyperWorks, LS-DYNA

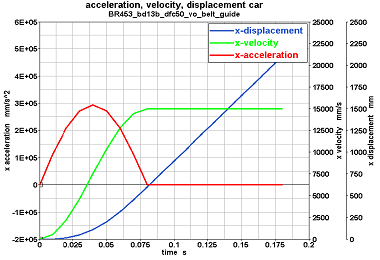

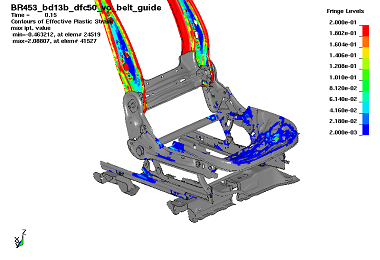

Analysis result

Figure-1: Analytical loading conditions Figure-2: Seat skeleton collision analysis

project description

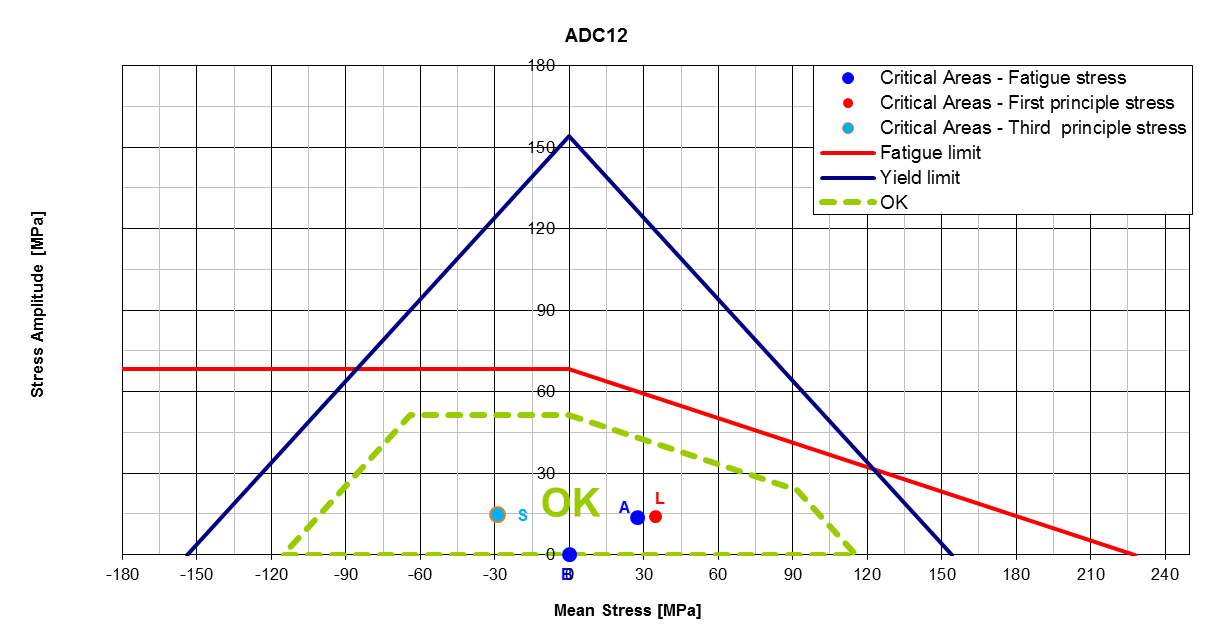

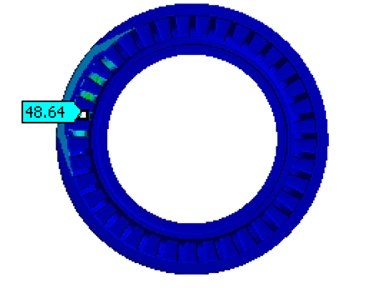

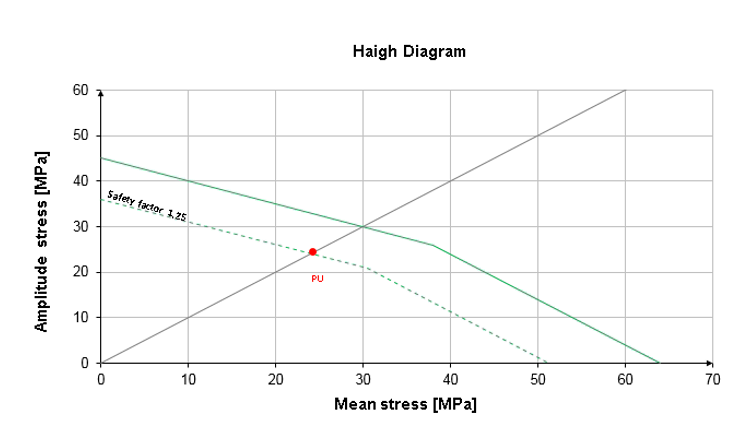

In the part design and development stage, we create the FEA analysis model based on the actual application conditions of the product, and analyze the stress distribution and alternating stress of the parts through FEA software, and finally evaluate the fatigue performance of the product.

Analysis content

Fatigue analysis of die-cast aluminum parts

Fatigue analysis of plastic wheels

Using the Software

ANSYS

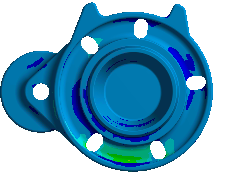

Analysis result

Figure-1: Fatigue analysis of die-cast aluminum parts

Figure-2: Fatigue Analysis of Plastic Wheels

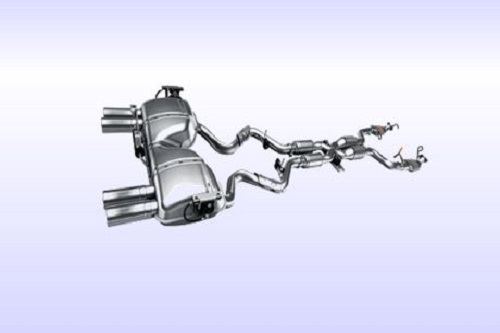

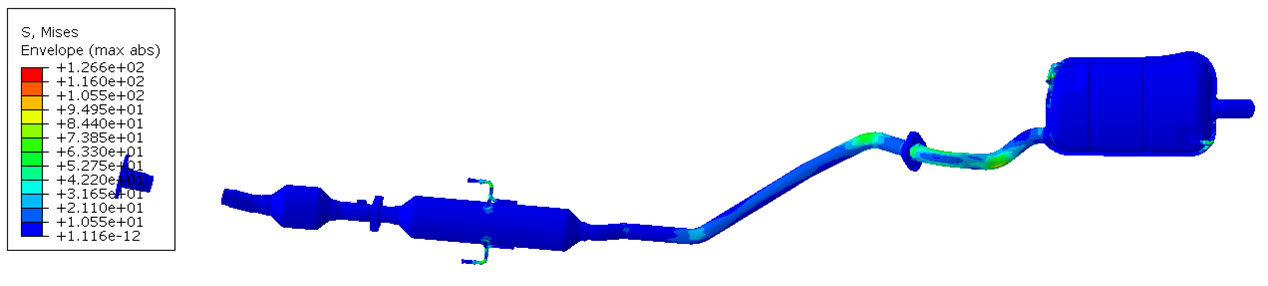

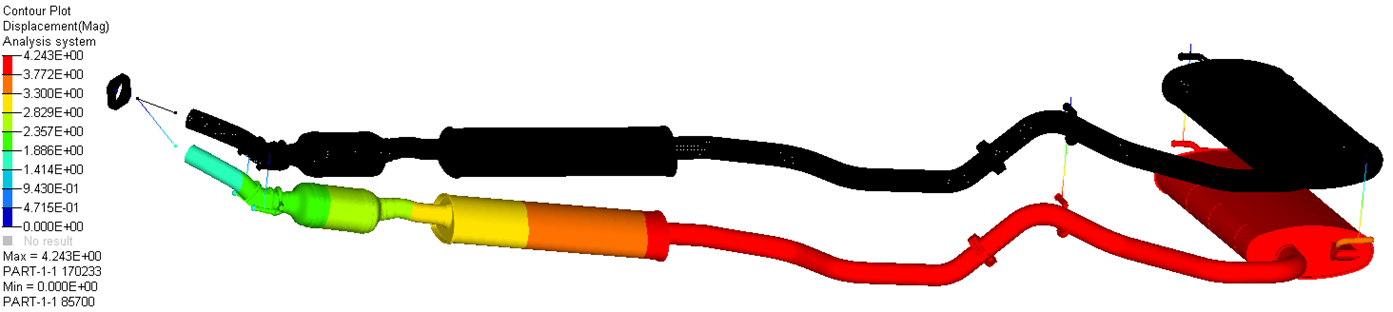

project description

In the design and development stage of the exhaust system, the CAE analysis model of the exhaust system is created, and the NVH characteristics of the exhaust system are analyzed by the application analysis software. The vibration of the exhaust system is mastered, and the optimization measures for selecting the suspension point of the exhaust system are proposed. The flow field characteristics of the exhaust system are analyzed to obtain the specific distribution of pressure, flow rate and temperature in the exhaust system, and the pressure loss of each main component is qualitatively calculated. To evaluate the overall performance of the exhaust system, and also to study the development and design methods of the muffler and exhaust system.

Analysis content

Heat transfer analysis

System thermal modal analysis

Thermal coupling analysis

Frequency response analysis

Static analysis

Using the Software

HyperWorks, ANSYS, ABAQUS, Nastran

Analysis result

Figure-1 Stress distribution and displacement of components under self-weight

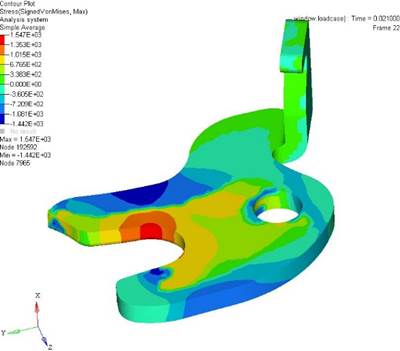

project description

The car door lock is an electromechanical integrated function system that is driven by the accessory to realize the safe closing of the door. It is a sports mechanism that integrates functionality, safety and decoration. In the design and development stage, CAE simulation, optimized structure and reasonable material selection. Design the best product.

Analysis content

Static strength analysis

Random vibration simulation analysis

Using the Software

HyperWorks, ANSYS, ABAQUS, Nastran

Analysis result

Figure-1: Static Strength Analysis

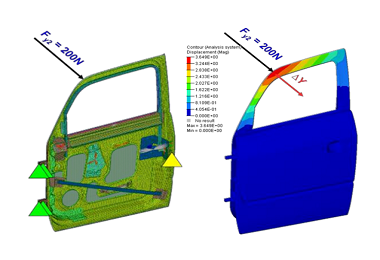

project description

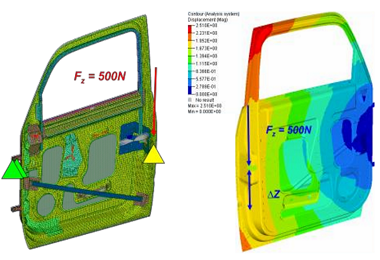

During the side impact of the car, the rigidity of the door plays a vital role in protecting the members. Through the simulation analysis of the door, the stiffness performance of the door can be investigated and appropriate improvement suggestions can be provided.

Analysis content

Horizontal stiffness analysis

Vertical stiffness analysis

Using the Software

HyperWorks, ABAQUS

Analysis result

Figure-1: Horizontal Stiffness Analysis Figure-2: Vertical Stiffness Analysis

Copyright © 2022 KunShan Acumen Precision Machinery Co.,Ltd. All Rights Reserved. 地址:No. 318 Youde Road, Kunshan City, Jiangsu Province 苏ICP备19021440号-1 XML地图 技术支持:风云网络