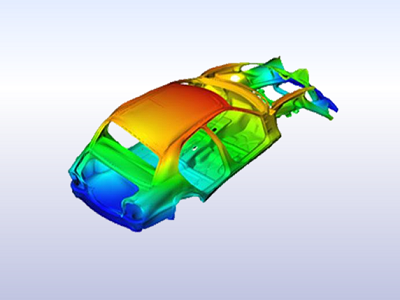

White body modal analysis

Car ride comfort analysis

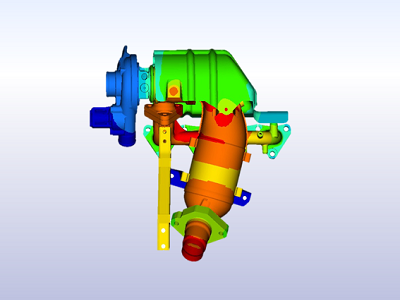

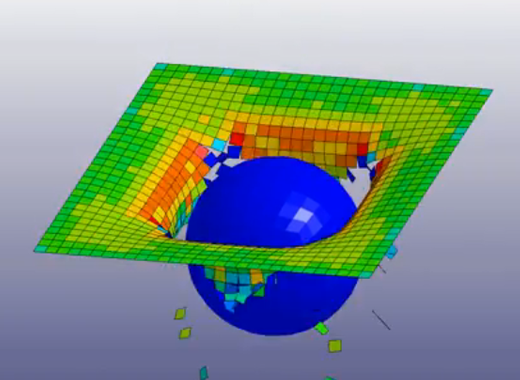

Vibration isolation analysis of automotive powertrain suspension system

Engine intake and exhaust noise analysis

Transmission and Response Analysis of Suspension System and Steering System to Road Roughness Excitation

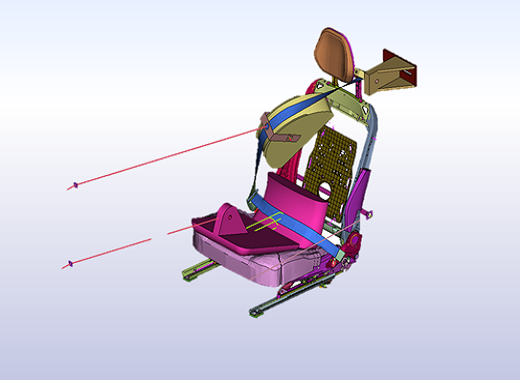

Analysis of ride comfort of drivers and passengers

Corresponding amplitude analysis of steering mechanism and instrument panel

Vibration and Noise Analysis of High-speed Flowing Air and Body Impact Friction

Analysis of the influence of the wear of gears, couplings and brake discs in the drive train on the NVH characteristics of the vehicle

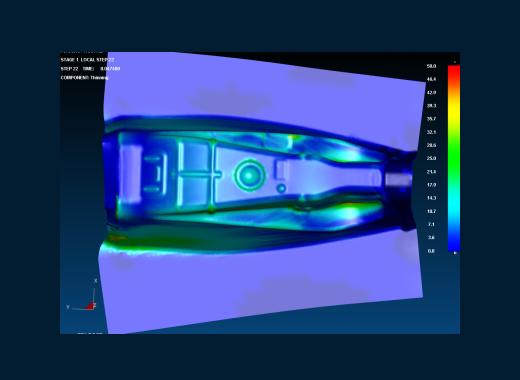

Analysis of drag coefficient of automobile external flow field

Noise analysis of starting flow field of automobile

Vehicle engine compartment thermal management analysisdefrost defoggingpneumatic noise source analysis

Analysis of engine in-cylinder combustion process

Fluid dynamics calculation of engine fuel supply system

Intake and exhaust system analysis

Cylinder cooling analysis

Thermal comfort analysis of automotive air conditioners

Seat frame strength analysis

Bicycle skeleton strength analysis

Seat belt fixed point strength analysis

Bumper tow hook strength analysis

Strength analysis of automobile beam bracket

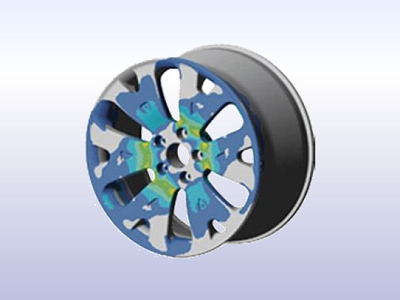

Strength analysis of wheel spokes

Strength analysis of engine components

Suspension structure strength analysis

Link Strength and Crankshaft Hole Distortion Analysis

Exhaust manifold crack, intake manifold strength analysis

Analysis of plastic deformation of front and rear bridges

Chassis strength analysis

Brake static analysis

Frontal 25%/40%/100% overlap collision

Back touch neck protection test

Moving barrier side impact test

Column side collision

Neck whipping test

AEB (pre-collision) test

Pedestrian protection test

Child protection project

Airbag test

Seat belt performance test

Luggage crash test

Roof strength test

Analysis Project

Toy products

Portable electronic products

Guideline

ISTA, ASTM, EN, GB

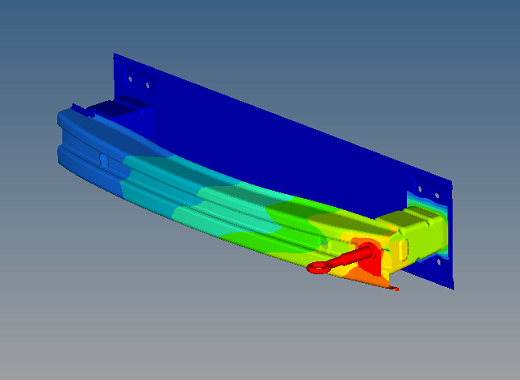

Front and rear longitudinal beam stamping simulation analysis

Simulation analysis of hood stamping

Simulation analysis of fender stamping

Side wall stamping simulation analysis

Top cover stamping simulation analysis

Door stamping simulation analysis

Simulation analysis of trunk lid stamping

Pipe fitting hydroforming analysis

Analysis Project

Contact fatigue

High temperature fatigue

Thermal fatigue

Corrosion fatigue

Fretting wear fatigue

Acoustic fatigue

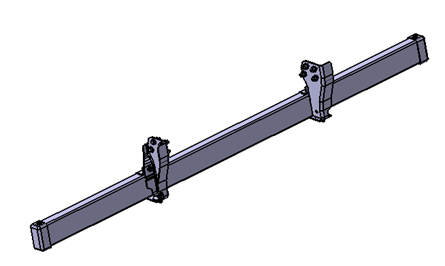

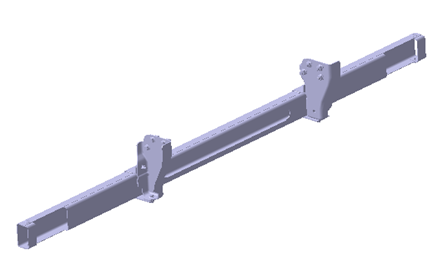

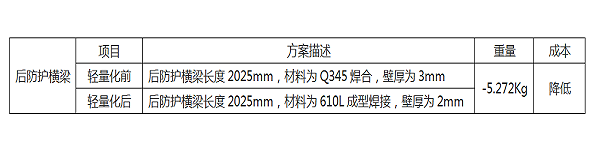

Rear protective beam size optimization

Before lightweighting, after lightweighting

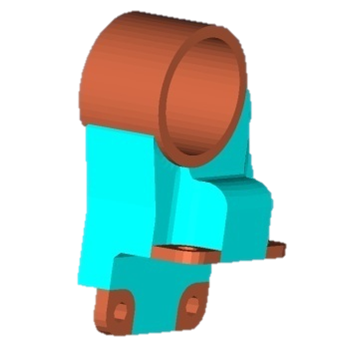

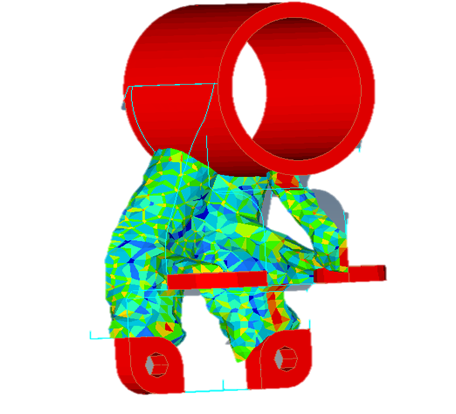

Suspension bracket topology optimization

The middle card front suspension bracket adopts topology optimization and light weight, and the weight is reduced from the original 19.3Kg to 6.8Kg and the weight loss is 64.7% under the premise of meeting the requirements of strength and collision safety.

Before lightweighting, after lightweighting

WeChat scan code

WeChat scan code

support hotline0512 - 57887651

mobile phone180-5112-3293

Copyright © 2022 KunShan Acumen Precision Machinery Co.,Ltd. All Rights Reserved. Add:No. 318 Youde Road, Kunshan City, Jiangsu Province 苏ICP备19021440号-1 XML Powered by Feng-Yun